A WIDE RANGE OF FILTER PANELS AND BAGS FOR WET FILTRATION.

Wound & Spun Cartridges -Liquids

When it comes to filter cartridges, we are able to provide the best quality products- Wound, Spun, and Pleated cartridge filters for your requirements.

We offer wound and spun (melt-blown) in wet filtration and pleated cartridges for use in dry filtration.

String Wound Polypropylene Filter Cartridges

(Also Available in Glass Fibre)

Below are the specifications of our Wound Polypropylene Cartridges:

Available in 10″, 20″, 30″ and 40″ lengths

Standard Diameters – 63 mm (Slim type) & 114 mm (Jumbo type)

Micron ratings available from 0.5 to 100 micron

Low Pressure Drop

High Dirt Holding Capacity

Made of FDA Grade Polypropylene yarn with PP core

No Fibre migration into the filtered product

Highly Stable media structure

Wound Glass Fiber with SS or TIN core also available

Melt Blown Polypropylene Filter Cartridges / Spun Polypropylene Filter Cartridges

Below are the specifications of our Melt-blown Polypropylene Cartridges:

Available in 10″, 20″, 30″ and 40″ lengths

Standard Diameters – 63 mm (Slim type) & 114 mm (Jumbo type)

Micron ratings available from 0.5 to 100 micron

Low Pressure Drop

High Dirt Holding Capacity

Made of FDA Grade Polypropylene

Single piece construction

Different cartridge weights available for domestic & industrial applications

as per requirementCustomization is possible in terms of length if required

Pleated Polypropylene Cartridges

All Polypropylene construction

Available in 10″, 20″, 30″ and 40″

Standard Micron ratings – 0.1, 0.45, 1, 5 micron

Thermally welded construction

FDA Approved raw material

Available in both DOE and Code 7 type construction

Request for Information

Sewn / Welded Filter Bags -Non-Woven Polypropylene and Polyester

We offer Welded Flange Top and Welded Seams (Sewn) Filter Bags for Liquid Filtration. Impenetrable welded seams improve filtration and in conjunction with a glazed finish on the filter bag, greatly reduce or eliminate fiber migration. For certain applications, Welded seams offer an advantage over sewn seams.

We offer Welded Flange Top and Welded Seams (Sewn) Filter Bags for Liquid Filtration. Impenetrable welded seams improve filtration and in conjunction with a glazed finish on the filter bag, greatly reduce or eliminate fiber migration. For certain applications, Welded seams offer an advantage over sewn seams.

The bottom, side, and Flange top of the Welded Seam Filter Bags for Liquid Filtration is completely welded. No thread is used, and no sewing holes exist.

Although our standard Welded Seam filter bags are made with glazed media, plain media in many of the above micron ratings can often be provided.

With a wide range of micron sizes we can support and partner with many industries like chemical, food, paper, petroleum, adhesives, paints, water treatment, beverages, pharmaceutical and more !

Sizes & Media

SIZES: Standard Welded Seam filter bags are available in:

7” x 16”

7” x 32”

4” x 10”

4” x 20”

7” x 36”

Media: Standard Welded Seam filter bags are available with:

Glazed Polypropylene felt media in 1, 3, 5, 10, 25, 50, 75, 100, and 200 microns

Glazed Polyester felt media in 1, 3, 5, 10, 25, 50, 75, and 100 microns

Nylon Filter media bags are also available

Uses in Water Filtration - Effluent Treatment and Incoming Water Filtration

Incoming Water Filtration is required in water intensive process plants such as dyeing, pharmaceuticals and other industries.

Effluent Treatment Water is required to be filtered prior to discharge across all water-intensive process plants.

Our bags are available in different micron sizes to enable our clients create a more sustainable planet and ensure that there is no contamination in their process houses.

Request for Information

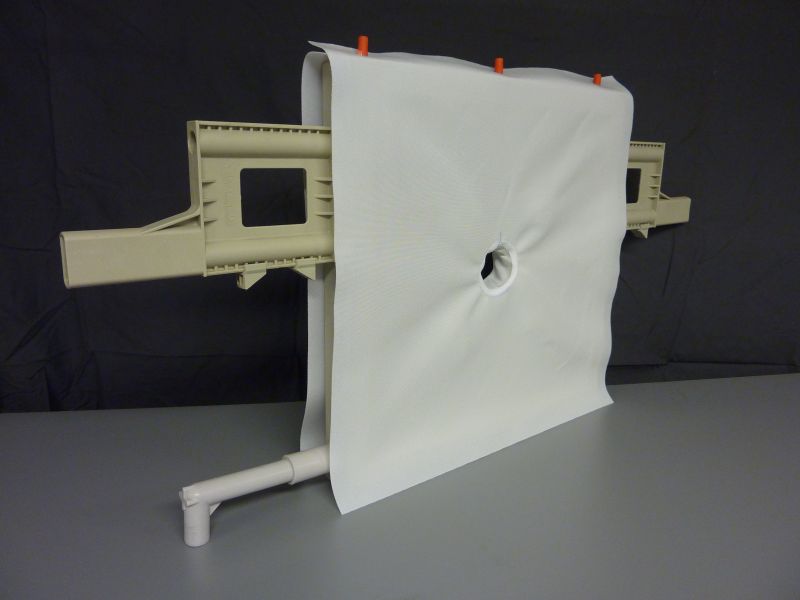

Filter Press Cloths – Panels / Butterfly

We offer a full range of woven and non-woven filter press panels that are utilized extensively in the filtration of Edible oil, lubricants, clay, chemicals and drugs.

Filter Presses Overview

The objective of Filter press is to use a high pressure environment to achieve solid/liquid filtration. As high quality filtration and cake recovery are the goals, the choice of filter media is important as the media has to sustain the high pressure environment, and enable high rate of throughput and quality.

Our Range of Filter Press Cloth

We offer a full range of woven and non-woven filter press panels that are utilized extensively in the filtration of Edible oil, lubricants, clay, chemicals and drugs

Usually applied in non-acidic or neutral environments

For cotton filter press panels, our precision cutting and stitching includes strong reinforcements of the edges and circles cut out to enhance durability

For synthetic filter media, we perform heat cutting and sealing, to ensure a high durability and precision cutting.

Request for Information

Centrifuge Bags

Get high quality Centrifuge bags for your wet filtration needs from Technical Textiles India. Centrifuge bags are utilized extensively by pharmaceuticals, chemicals and drugs manufacturers.

Centrifuge bags are utilized extensively by pharmaceuticals, chemicals and drugs manufacturers. As centrifuges are typically used in acidic environment, polypropylene is widely used for top lifting, top discharge and bottom discharge centrifuge bags.

Centrifugal energy is used in such a way that the wall of the centrifuge is the media and permits the filtrate to go through while leaving the solids on the surface. These solids can be put to wash and then detached continuously by an unloading knife and discharged out from the particular means.

Technical Textiles India a leading supplier of centrifuge filter bags to customers in pharmaceuticals, chemical processing, fertilizers, food processing, etc. Our centrifuge bags are custom-stitched to your specifications and provide you and optimal balance between production and quality.

A complete solution

To provide customized filter bags, we begin with an assessment of the process to understand particle retention and flow rate requirements to suggest the right fabric to be used in terms of the weave and yarn (spun/ mono or multi-filament yarns)

Request for Information

Nutsche Filter Bags

Nutsche® filter bags are usually made from specialized polypropylene filter cloth, which is a woven cloth made from specialized polypropylene fiber yarns widely chosen for its high strength and excellent resistance to most acids and alkali.

Nutsche® Pressure Filters, which operate under either vacuum or pressure to separate liquids from solids. Nutsche® filter bags are usually made from specialized polypropylene filter cloth, which is a woven cloth made from specialized polypropylene fiber yarns widely chosen for its high strength and excellent resistance to most acids and alkali.

Since its moisture absorption is virtually nil, Polypropylene fabric is a good choice for separation applications where the liquid is the final product. Bags can be constructed either with a flange, or with a drape, according to your specifications. Seams are constructed using our exclusive "lock-stitch" resulting in durability and dependability.

Customized Nutsche® Filter Bags

We provide customized filter panels for Nutsche® Filters/ Agitated Nutsche® Filter Bags / ANFDs. Agitated Nutsche® Filter (ANF) is a filtration technique used in applications such as dye, paint, and pharmaceutical production and waste water treatment.

The Nutsche® filters in its full configuration consists of four major components:

The vessel

The filter floor and cloth, woven mesh screen or sintered metal plate medium

The re-slurry arms for cake washing and smoothing

The cake discharge mechanism

With our experience in working with different types of slurry, we can offer a wide choice of materials of specific weaves, particle retention, and other specialized properties.

Request for Information

Coolant Filter Papers

We supply continuous band coolant filter papers of varying particle retention size to retain the particles from the contaminated filter media. The clean coolant filters out through the fabric leaving a “cake” of the metallic particles.

What are Coolant filter Papers?

Coolant Filter Papers are typically used in the machine tool process to separate metal debris and dust from the coolant, enabling the coolant to be recycled and precious metal waste to be reutilized.

We supply continuous band filter papers of varying particle retention size to retain the particles from the contaminated filter media. The clean coolant filters out through the fabric leaving a “cake” of the metallic particles.

Our range of Coolant Filter Papers

Technical Textiles India provides a wide range of options for coolant filter paper options

Type: Adhesive bonded, synthetic filter papers and more

Materials: A Diverse set of materials such as polypropylene, polyester, cellulose, polyester, and vinyl is available

Gram-mage and Particle retention capability is determined by the gram-mage, weave, and construction of the fabric

Our high-grade Filter Paper is relatively inexpensive for all functions

Request for Information

Rotary Vacuum Drum Filter Cloth

Our wide range of woven and non-woven Rotary Vacuum Drum Filter Cloth allows you to balance throughput, cake discharge, and long-life.

What are the Rotary Vacuum Drum Filters?

The rotary drum vacuum filters, a workhorse of the chemical process industry for many years, has been designed for long life and easy maintenance. These filters involve half of the drum being submerged in the slurry and the other half above it. The Filter Cloth or belt winds around the drum, and as the drum rotates, the slurry is sucked into the cloth. As the drum rotates, the cake is dried using vacuum pressure on the exposed area, and the cake is formed. The dried cake is discharged as the drum rotates.

Our range of Rotary Vacuum Drum Filter Cloths

Our wide range of woven and non-woven media allows you to balance throughput, cake discharge, and long-life.

High particle retention, bursting and tearing strength, and abrasion resistance of the fabric besides chemical and thermal compatibility are important. Besides, abrasion resistance is required as the process of removal of the dried cake involves scraping.

Our quality Filter Cloth withstands the rigorous scraping process used to remove the dried cake.

We often recommend a double-layered fabric to ensure the longevity of the filter cloth and better separation. Hence, we also offer a knitted nylon backing fabric that can be used underneath the top cloth to provide a cushion and stability for the cloth as it moves through the Rotary Drum process

Innovative agitator rake design ensures solids remain in suspension and avoids

sediment in the system tank for better materials distributionWide range of choices for drum material to suit process demand– polypropylene, carbon steel (unlined or rubber-lined), stainless steel, as well as other materials

To consult our expert technicians to see which cloth would work best in your application, please fill the form below:

Request for Information

Vacuum Belt Filters

Our Vacuum Belt Filter Bags utilize polypropylene fabrics with high bursting strength, great particle retention (specific fabrics are suggested based on the micron size), and high chemical compatibility.

What are Vacuum Belt Filters?

The vacuum belt filter is used for the filtration of liquids and de-watering of sludge, which are rich in solids, quite often about 50-60% of the slurry. The vacuum belt filter utilize gravity along with additional vacuum support, by using fixed vacuum trays with a continuously moving belt on top of the same. The belt may move continuously or in steps in sync with the slurry feed. As a result, higher throughput and better de-watering of the filter cake can be achieved. Depending on the application, filter fleeces or endless filter belts are used.

Cake washing is accomplished by nozzle sprays or drying by vacuum.

Our range of Vacuum Belt Filter Fabrics

Our vacuum belt filters are tailored to customer specification.

We utilize polypropylene fabrics with high bursting strength, great particle retention (specific fabrics are suggested based on the micron size), and high chemical compatibility.

Industry applications of vacuum Belt filter applications include:

Hydro-metallurgy

Purification of minerals and base metals

Benefaction of minerals

Sewage filtration

Removal of chloride and other contaminants

Pump filtration from thickener under-flows

Flotation pump filtration to recover concentrates

Request for Information

Disc Filter Bags

Disc Filter Bags are used when the concentration of the solid in the slurry is very low. Hence, the choice of the fabrics for the disc filters is mandated by a high rate of throughput but with good particle retention

Disc Filter Bags are used when the concentration of the solid in the slurry is very low. Hence, the choice of the fabrics for the disc filters is mandated by a high rate of throughput but with good particle retention. Further, the ease of cake discharge is important as well.

Factors that determine the choice of Disc Filter Media

High throughput rate with good particle retention capabilities

Typically, polypropylene fabrics are preferred

Long service life is important and is determined by the type of material, customized fabric construction to the type of slurry and the size of particles to be retained

Technical Textile India’s range of Disc Filter Bags

We offer disc filter bags in a wide range of materials to suit different types of slurry, pore sizes to ensure high-level of political retention, and in fabric constructions that balance the need to retain the particles with high flow rates.

Bags are custom-made with a special zipper or velcro closures as well as edge reinforcement and dedicated sealing to ensure highest possible vacuum levels.

Request for Information

Sparkler Filter Pads

Technical Textiles India provides disposable as well as re-usable Sparkler filter pads from woven and non-woven fabrics.

What are Sparkler Filters?

Sparkler Filter pads are concentric circles that are put together in a filter cartridge assembly. The inside shell of the assembly comprises of the pre-arranged filter plates with perforated sustaining screens, sparkler filter pads, and inter-locks. The assembly is complete with pump and piping connection mounted on a stainless-steel trolley. The contaminated liquid to be filtered is fed to the filter shell by a pump. It flows through the top of each plate through the opening on the sides of the plates. As liquid pressure increases, the filter media (Paper/fabric) holds back the impurities & allows the crystal-clear filtrate to go by through the central channel (formed by interlocking cups) which takes the filtrate to the exit of filter.

Sparkler filter pads are typically used to get the clear fluid. Sometimes the cake formed between the plate is also obtained. Filtration is continuous until its rate reduces due to augmented cake resistance.

Our range of sparkler filter pads

Technical Textiles India provides disposable as well as re-usable Sparkler filter pads from woven and non-woven fabrics.

The materials include Polypropylene, Cotton, Nylon, and Polyester

In some cases, specialty fabrics are also used

These are used extensively in the pharmaceutical and chemical industries on sparkler filter presses

All our sparkler filter pads are heat sealed or have reinforced edges to provide longer life.

Wide range of media choice ensures high chemical compatibility and high resistance to the type of slurry

Request for Information

Explore our Range of Wet and Dry Filtration Products

Wet Filtration

Dry Filtration

Contact

Technical Textiles India

No: 4, Ekambaram Estate,

Off:Arcot Rd, Allapakkam,

Porur, Chennai -600116

Tamil Nadu, India

p:+91 99410 14633

p:+91 98400 20554

Email