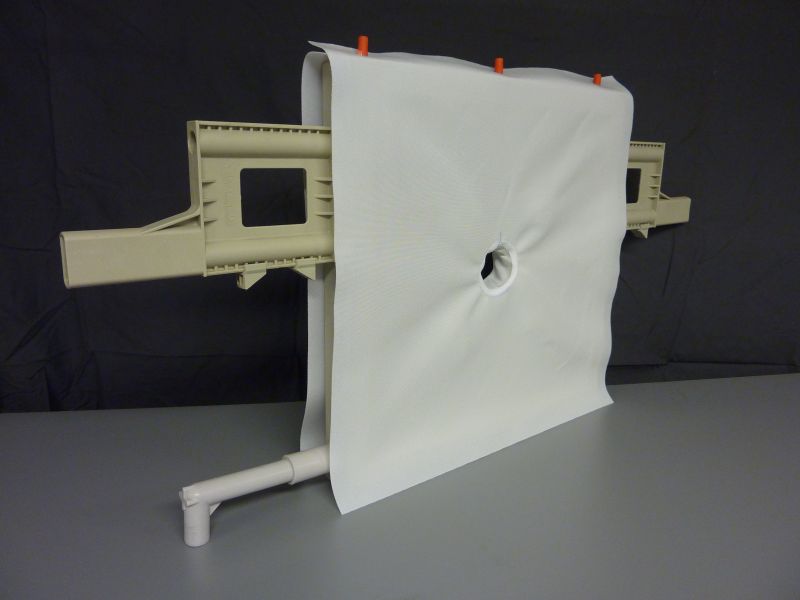

Filter Press Cloths – Panels and Butterfly for Optimized Filtration

Technical Textiles India offers high-performance Filter Press Cloths tailored to enhance the efficiency of liquid-solid separation processes in a variety of industrial settings. Choosing the right filter cloth is crucial, as it significantly impacts filter press operations' operational efficiency and effectiveness.

High-Efficiency Advanced Materials for Filter Presses

Why is Filter Cloth Selection Critical?

Selecting the appropriate filter cloth involves considering several key factors to ensure optimal performance, including resistance to blinding, ease of cake discharge, chemical and thermal resistance, and durability. Our expert team at Technical Textiles India is equipped to guide you through selecting the perfect cloth for your needs, ensuring superior filtration results.

Filter Cloth Materials and Advantages

We provide a wide array of fabric options, each offering unique benefits suited to specific filtration requirements. Here’s a detailed look at our fabric types and their respective advantages:

| Fabric Type | Advantages |

|---|---|

| Woven Nylon | Excellent abrasion resistance, good for alkaline and organic environments. |

| Woven Cotton | High absorbency, suitable for food-grade applications. |

| Woven Polypropylene | Resistant to acids and alkalis, ideal for chemical processing. |

| Woven Polyester | Strong, durable, and resistant to abrasion. |

| Non-Woven Polyester Needle-Punched | Durable, balances permeability and particle retention, good for general applications. |

| Non-Woven PTFE Needle-Punched with Membrane | High filtration efficiency, excellent chemical resistance, ideal for harsh environments. |

| Non-Woven PTFE Needle-Punched without Membrane | Greater flow rates, excellent chemical resistance, suitable for less aggressive filtration. |

Filter Cloth Yarn Designs and Weave Patterns

Choosing the right yarn design and weave pattern can significantly affect the filter cloth’s performance. We offer various designs and patterns to suit different operational needs:

Multifilament Yarns: Enhance strength and particle retention.

Monofilament Yarns: Provide smooth surfaces for easier cake release.

Spun Yarns: Offer flexibility and good abrasion resistance.

Weave patterns like plain, twill, satin, and leno are chosen based on the desired balance between cake release characteristics, abrasion resistance, and particle retention.

Filter Plate Compatibility

Our Filter Press Cloths are compatible with all major types of filter plates, including recessed, non-gasketed, membrane, and plate-and-frame configurations. This ensures seamless integration with your existing systems.

Applications Across Industries

Technical Textiles India’s Filter Press Cloths are extensively used across various sectors, enhancing filtration processes and achieving compliance with stringent industry standards:

Mining and Mineral Processing: Essential in the dewatering of mine tailings and mineral concentrates, facilitating the recovery of valuable minerals while minimizing environmental impact.

Chemical Manufacturing: Critical for the filtration of fine chemicals, including acids, solvents, and reactive substances, ensuring product purity and operator safety.

Food and Beverage: Used in the clarification of liquids such as wine, beer, and edible oils, ensuring clarity and quality while meeting regulatory compliance.

Pharmaceuticals: Supports sterile filtration processes, essential for the production of pharmaceuticals where contaminant-free results are mandatory.

Environmental Management: Plays a pivotal role in wastewater treatment plants and sludge dewatering facilities, helping to meet environmental discharge standards.

Oil and Gas: Filters drilling muds and refinery wastes, aiding in the efficient extraction and processing of oil and gas.

Water Treatment: Crucial for the prefiltration of drinking water and desalination processes, enhancing the efficiency of reverse osmosis systems and reducing membrane fouling.

Leverage our expertise and high-quality materials to enhance your filter press operations.

Contact us today to discover how our tailored Filter Press Cloths can meet your specific filtration needs and help achieve your operational goals.